Hatsukokoro STRIX K-Tip Sanmai Gyuto 240mm

Hatsukokoro STRIX K-Tip Sanmai Gyuto 240mm is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Detailed Specifications

| Line | Hatsukokoro by Sukenari STRIX Sanmai |

| Profile | Gyuto / Chefs Knife |

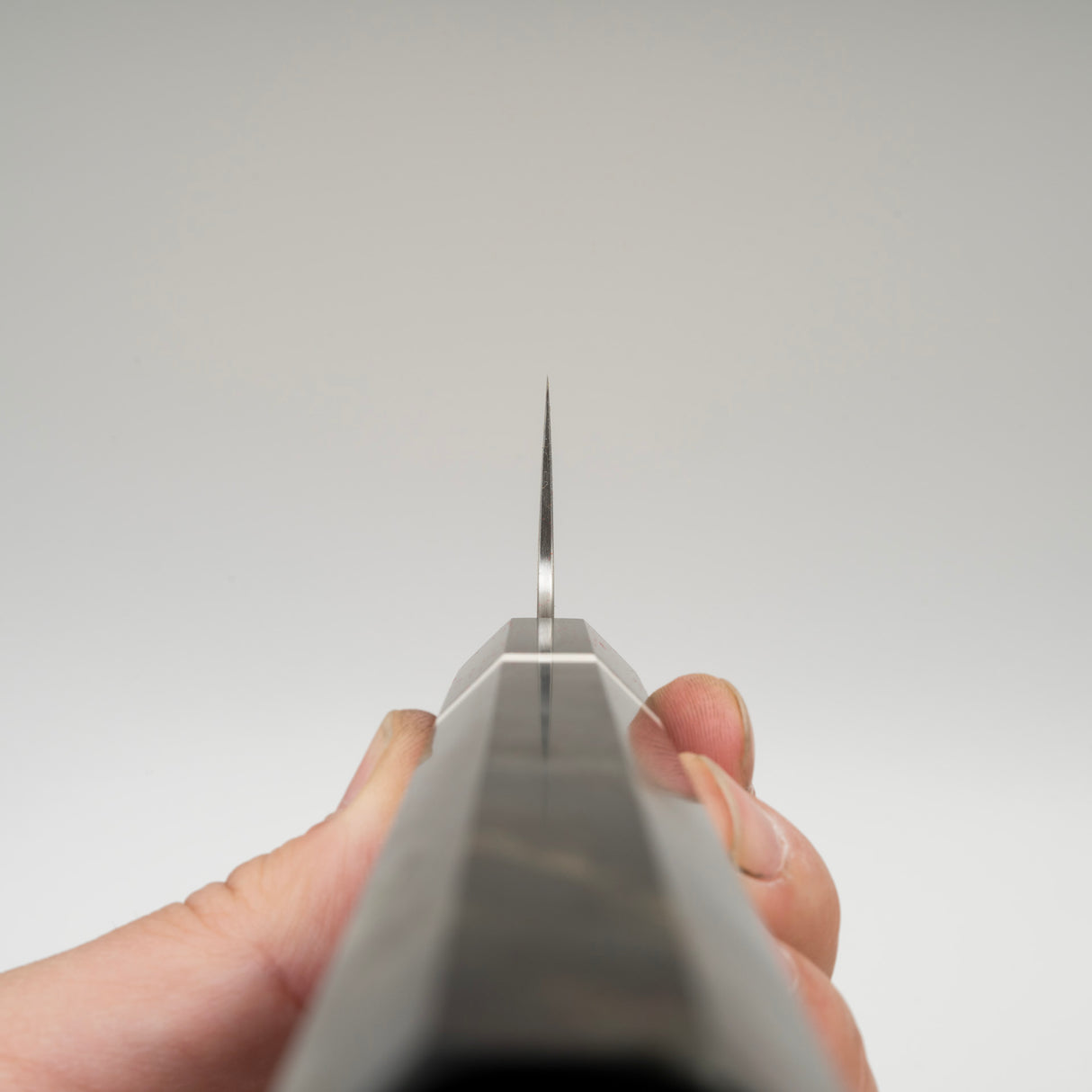

| Bevel Type | Double Bevel |

| Weight | 227 g 8.01 oz |

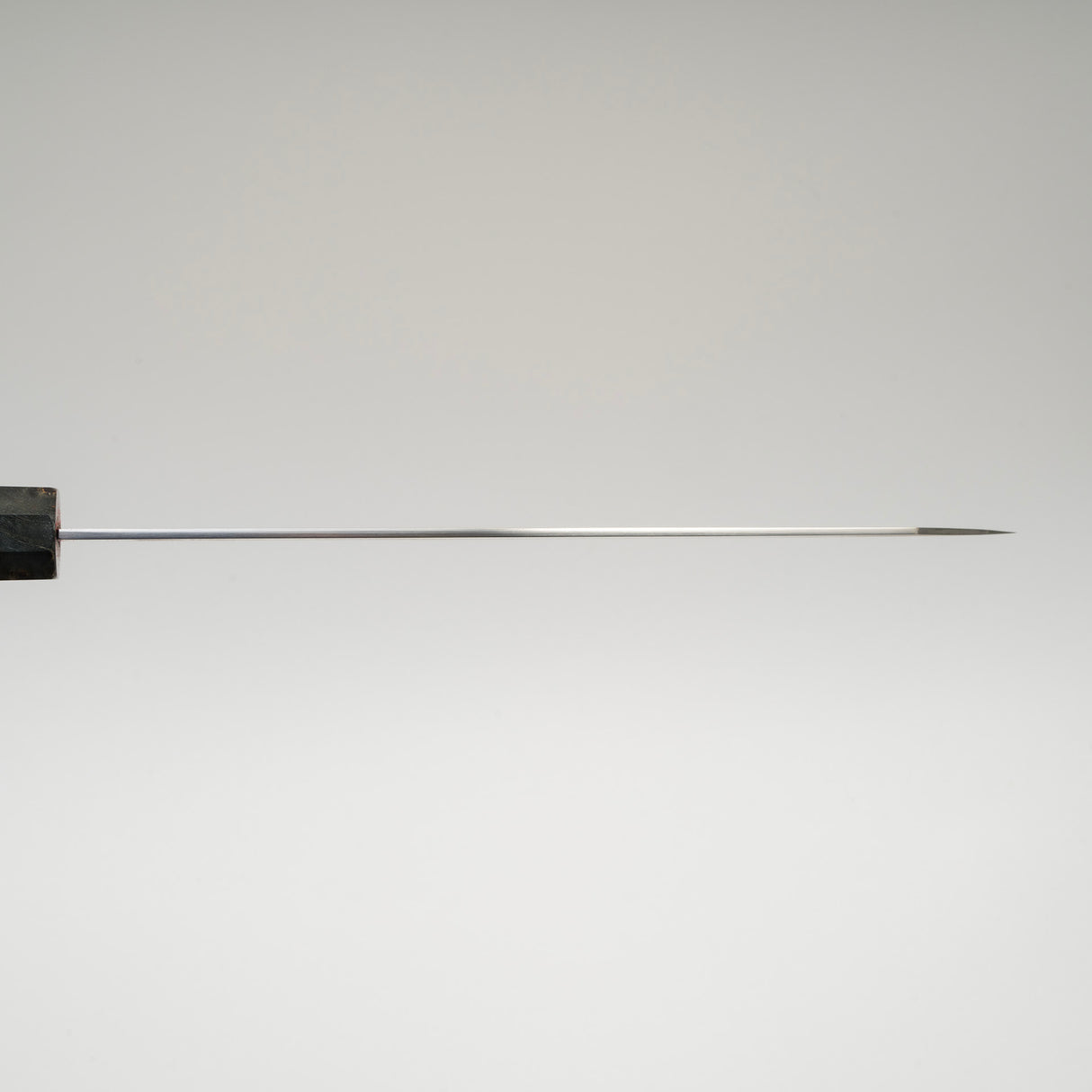

| Edge Length | 232 mm .9.13 inch |

| Heel Height | 52 mm .2.05 inch |

| Width @ Spine | 2.5 mm 0.1 inch |

| Width @ Mid | 2.3 mm 0.09 inch |

| Width @ 1cm from Tip | 1.1 mm 0.04 inch |

| Steel | SPG STRIX | Powdered Stainless |

| Blade Construction | Sanmai - Stainless Clad |

| Hardness (HRC) | 63 - 65 |

| Surface Finish | Migaki |

| Handle | Octagonal Birch Burl with Spacer |

| Region | Toyama |

| Best for |

|

| Pros | Cons |

|

|

|

Care Instruction

- Don't cut hard things! Japanese knives are brittle so bone hacking is a NO NO!

- Wash with neutral detergent after use, and wipe dry;

- Please don't wash knife with dishwasher, it will damage the wood handle;

- Be careful not to leave the knife close to a heat source for a long time;

- It is a lot more dangerous to cut with a blunt knife than a sharp knife!

- It is best to sharpen a Japanese knife regularly on a waterstone.