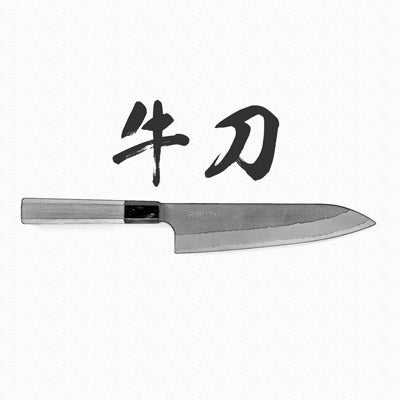

The Nigara Honyaki line, with their stunning etched finish and dynamic Hamon, finally start to arrive the shop in batches. These blades is another step up from the very popular Anmon(暗紋) line in terms of artistic value, which also put up a strong statement that Nigara shall glorify its 350 years of extensive sword forging history with this highly skill demanding practical art.

The Honyaki line from Nigara is made with Hitachi White 1 or Blue 2 steel, these are the more pure carbon steels with the Blue 2 have a small amount of alloy content introduced to it, they are characterised by the ablility of getting a very keen edge, hold sharp for an extensive amount of time and be very easy to sharpen at the same time. Both steel belongs to the Hitach Yasugi Carbon Steel family, which is composed of different grade carbon steel, originally developed to replace the scarce Tamahagane - the steel smelted in a acient way to make all kinds of traditional edged tools, including the Katana.

Once a regionally famous maker of Katana, Nigara as a brand have been passing down this craft for over 350 years, now headed by the 8th gen bladesmith Tsuyoshi Yoshizawa(吉澤 剛), the brand is making a comeback to this traditional skill with their Honyaki line, throught some remarkable artistic features that are reminiscent to traditionally forged Katana.

The Honyaki knives are made in very similar ways to the katana, both involves extensive forging and differential hardening using clay. The shape and quality of Hamon(波紋, wavy pattern formed on the boundary of hardened edge and softer spine through applied clay)appeared on the Katana and Honyaki knives can often differentiate their artistic values. Often the kitchen knives are made with very regular pattern, with less dynamic look compare with Hamons found on Katana. However, some of the Nigara's Honyaki have clearly departed from this way and created much more dynamic Hamons with features like strong Nioi and Boushi that are very comparable with Katana. In terms of how wild the Hamon is, maybe Hashimoto's Honyaki is the only thing that is on par with these knives.

Another feature that is unique to the Katana is the pattern formed when the Tamahagane are folded over and over, this process distribute the impurities and alloys evenly across the blade to obtain a uniform strength across the blade, as the result, different elements are stretched out along with the steel and lead to various types of patterns.

Forged with a homogenous steel coming out of modern factory, the Nigara Honyaki blades requires no folding to gain the uniformity, but as they are hand forged into shape out of a billet, they need to get heated over and over under certain temperature, so they don't lose carbon content through oxidation. In this heating-forging process, the alloy content would precipitate out, as they get stretched with the forging of the blade, they will form pattern that is quite similar to the folding pattern on the Katana. This is called alloy banding, a phenomenon that can be found on only forged, not stamped blades.

The alloy banding marks the intense labour and remarkable skill behind the creation of the blade and add another layer of texture onto the blade. The Nigara Honyaki line, with all the blades receive a etching finish, reveals the banding with a high contrast so they can be observed easily in all kinds of lighting condition. Combines with the unique Hamon, I can seeNigara's a intent to proudly show the skill they pocessed over the brand's long history.

These precious blades will be sold as standalone items, please refer to the specific item for the spec and pictures.